I’ve tried to report the issue to Prusa support but they keeps trying to diagnose it as user error. But at this point I’m at a loss and presume that it’s either a firmware issue or a sensor issue on my unit.

Either way im very disappointed.

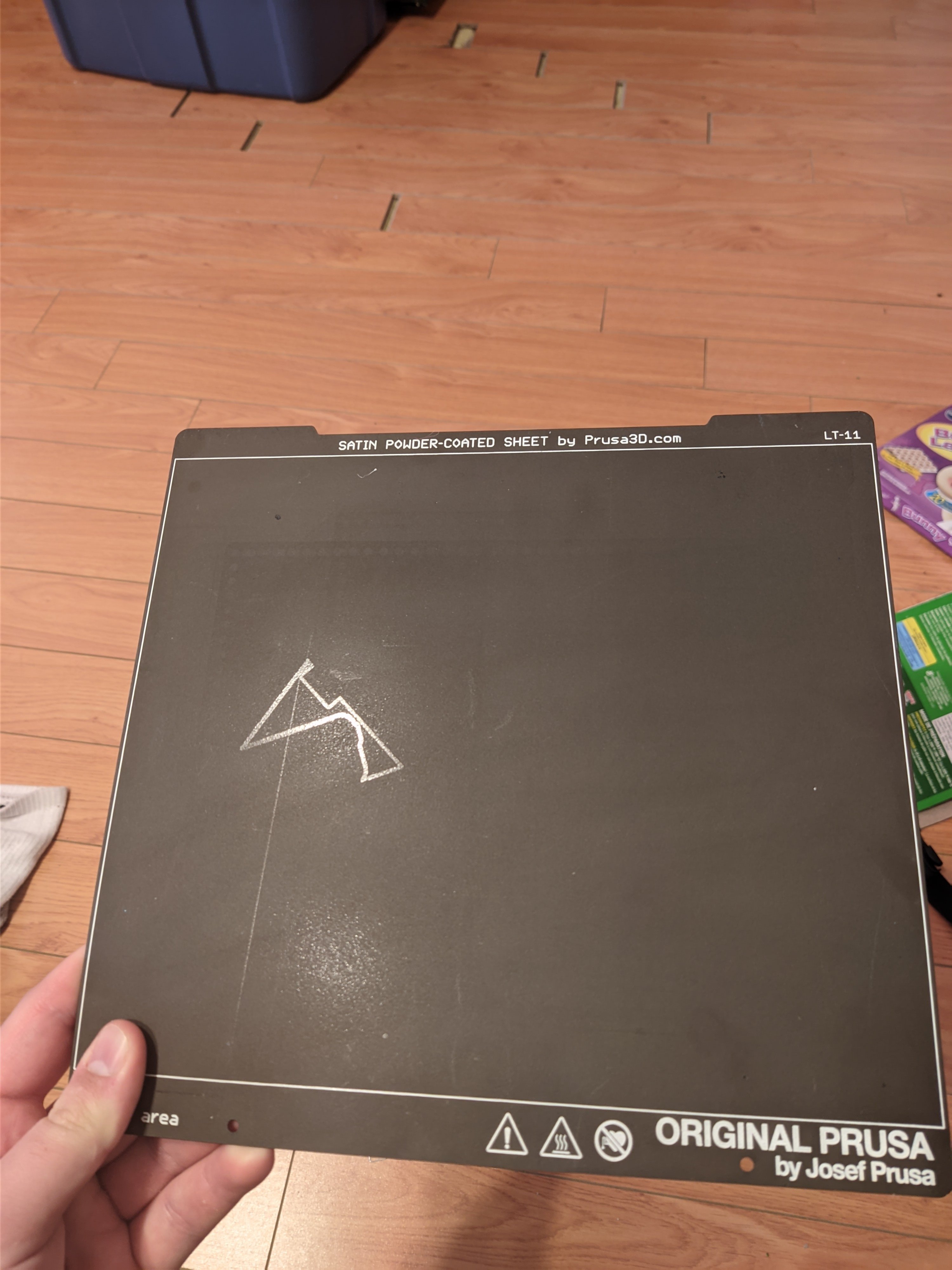

And before you ask, this is the opposite side

EDIT: I will note that this print sheet is ruined for my use case, since those patterns will be shown on the underside of my prints. But the print surface still works and can be used without issue… if you ignore the gouges that are being detailed into every print.

If you’re bed leveling with a heated nozzle, you’re not doing it right.

Shouldn’t you make your adjustments while the bed and nozzle are at least partially heated, since metal expands when heated? If you adjust z-offset when cold, the nozzle may expand a bit, decreasing the gap. At least that’s my understanding, and why most printers I’ve seen will preheat the bed and nozzle before doing bed leveling

If you’re using something like a tap or anything that uses the nozzle as the probe then you do want the bed and nozzle to be at temp (or close) so any thermal expansion is included.

Same applies if you’re using something like auto Z offset (since it’s going to be hit with the probe AND nozzle)

If you’re using something like a Klicky or BL touch then you need the bed to be temp but the nozzle doesn’t matter since you’re measuring with the probe. But… you do want the nozzle to be at temp when calibrating the Z offset so the right figure is used.

Personally… I have a Klicky (Klackender actually) and heat the bed and then dial in the zoffset with a print and baby stepping

Sure, but that doesn’t mean there won’t ever be some situation where it’ll try to Z home for whatever reason, or even if it’s just user forgetfulness, and you poke the PEI sheet with a 215+ degree nozzle. The fact that the mechanism inherently includes that possibility is stupid.

The printer won’t do any leveling with a fully heated nozzle.

The MK4’s we use at work and my personal MK4 all heat up to 170 before bed leveling, and if you previously swapped filaments before leveling, the printer will pause and wait until the nozzle has cooled down to the target range before initiating bed leveling.

Well, then at least they thought of that. Will it Z home with the nozzle preheated? I’ll bet you it will.